OUR MISSION

Connecting People with Japanese Style

Ando Co., Ltd., began as a manufacturer of tie-dyed fabrics centered on Kyo Kanoko Shibori, later expanding our business to include kimono accessories, the myriad items used to adorn traditional Japanese dress. Nowadays we incorporate tie-dyeing, Tsumami Zaiku craftwork, and other traditional Japanese techniques in the creation of not only traditional kimono accessories but also products for use in everyday life. Products that have been carefully crafted by artisans enrich the lives of the people who use them. Moving forward, we will continue to provide creations and services centered on Japanese techniques and Japanese culture.

LOGO CONCEPT

Changing the company logo

With an eye to the next 100 years, the company logo has been redesigned based on letters incorporating a sense of living an elegant and refined lifestyle while preserving tradition as well as an image of disseminating Japanese culture to the world.

ANDO'S SKILL

SKILL 01

Textile processing

From thread to fabric, we utilize techniques passed down from ancient times combined with the latest technology, seeking every day to generate new value.

Spinning

We restored throstle spinning machines that are no longer used in Japan and installed them in our Laos factory. Through throstle spinning-based manufacturing we aim to achieve development and symbiosis within the local community.

Textiles

We have everything from the latest high-speed looms to traditional handlooms. We tailor to our customer needs by using different types of looms according to the purpose and material of the product.

SKILL 02

Dyeing process

Tie-dyeing (dip-dyeing/Itajime), plain dyeing, gradation dyeing, inkjet printing—traditional dyeing artisans carefully dye each piece at our Kyoto Head Office’s dyeing atelier.

Tie-dyeing (dip-dyeing/Itajime)

"Fabrics are hand dyed by tying areas of the cloth with string and then immersing it in a liquid dye. When the string is removed, white patches are left where the dye could not penetrate, creating beautiful tie-dye patterns.

Itajime Shibori is a dyeing technique in which the cloth is folded and compressed tightly between wooden boards and then immersed in a liquid dye. Various different patterns can be created depending on how the cloth is folded and where the liquid dye soaks into the cloth."

Gradation dyeing

With this technique, parts of the cloth are immersed in the liquid dye for different lengths of time and absorb different concentrations of dye. This enables the creation of soft beautiful gradations.

Plain dyeing

In plain dyeing, pieces of cloth are hung on slowly rotating rods so that they are not touching while immersed in the liquid dye. This technique is mainly used for dyeing silk products.

Inkjet printing

This technique enables the creation of tens of thousands of colors and does not require a mold. Inkjet printing enables small-lot production of natural fibers.

SKILL 03

Sewing machine processing

From handwork to the latest machines, we utilize a range of processing techniques to enhance the added value of the products.

Sewing

Yukata, Jinbei, and Kinchaku are carefully sewn together by our skilled staff. Processing location is selected from among our three production bases—in Japan, China, and Laos—according to the process.

Embroidery

Our Makino Branch is equipped with 11 embroidery sewing machines, enabling us to respond flexibly to requests regarding lots and delivery dates.

SKILL 04

Handwork

Our artisans carefully make each item individually by hand.

Tsumami Zaiku craftwork

Small, thin pieces of fabric are folded and styled to look like flower petals then attached to a stalk. This handwork requires patience, but the finished accessories are delicate and exquisitely beautiful.

Braided cords

Silk threads dyed gorgeous colors are woven by hand. Hand over hand, traditional braided cords are created through the combination of colors and patterns.

SKILL 05

Footwear production

Straw sandals, wooden clogs, and other footwear are created in our factory using more than 50 processes, including handwork.

QUALITY & SAFETY CONTROL

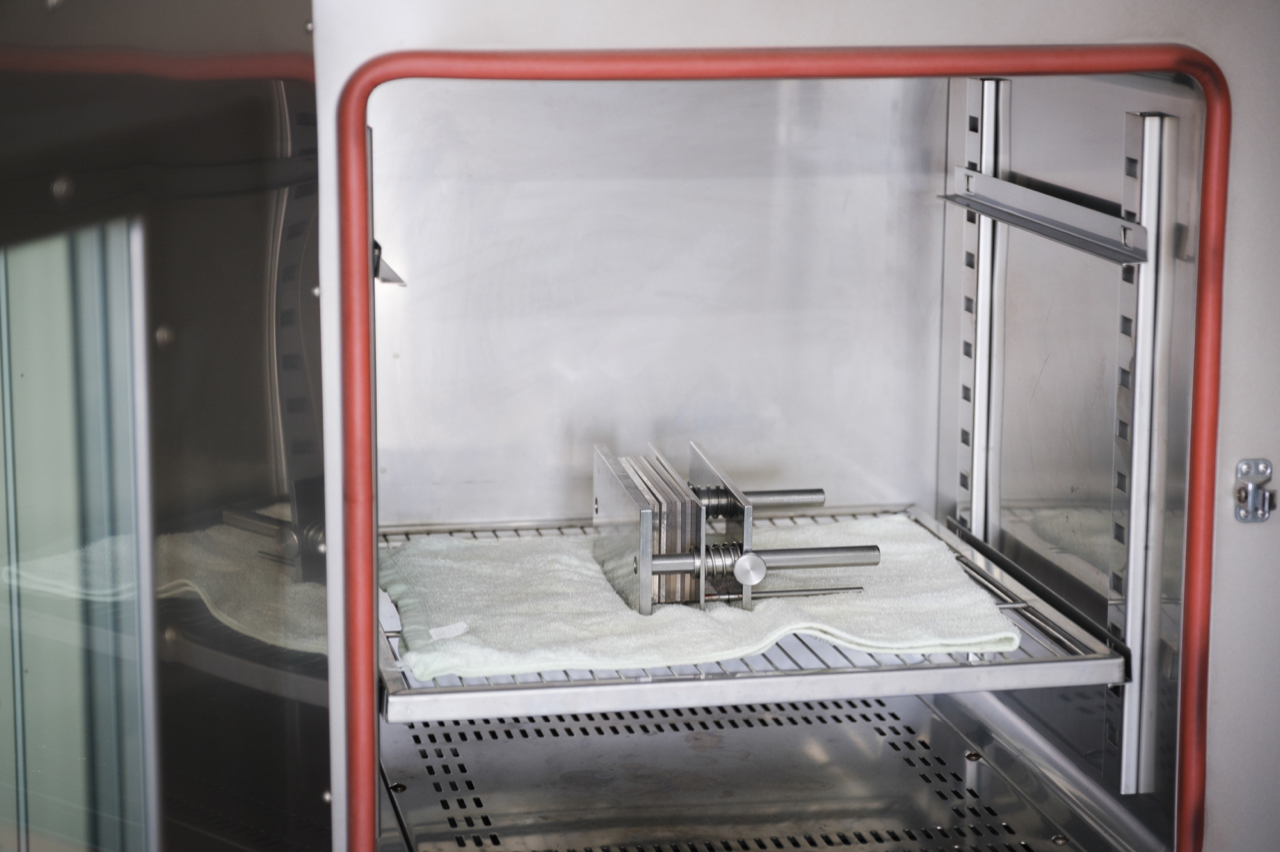

Water test/perspiration test: - JIS L 0846/0848

This test ascertains the extent to which color transfer occurs when dyed products that are wet with water or perspiration are in contact with other products for a long period of time. Testing is carried out at a near body temperature of 37℃ to simulate conditions when the products are being worn.

Friction test: - JIS L 0849 II Type

This test ascertains the extent to which dyed products rub together or color transfer occurs when the products are in contact with other products while being worn. Testing is carried out under dry conditions or wet conditions, such as when the products are wet with rain.

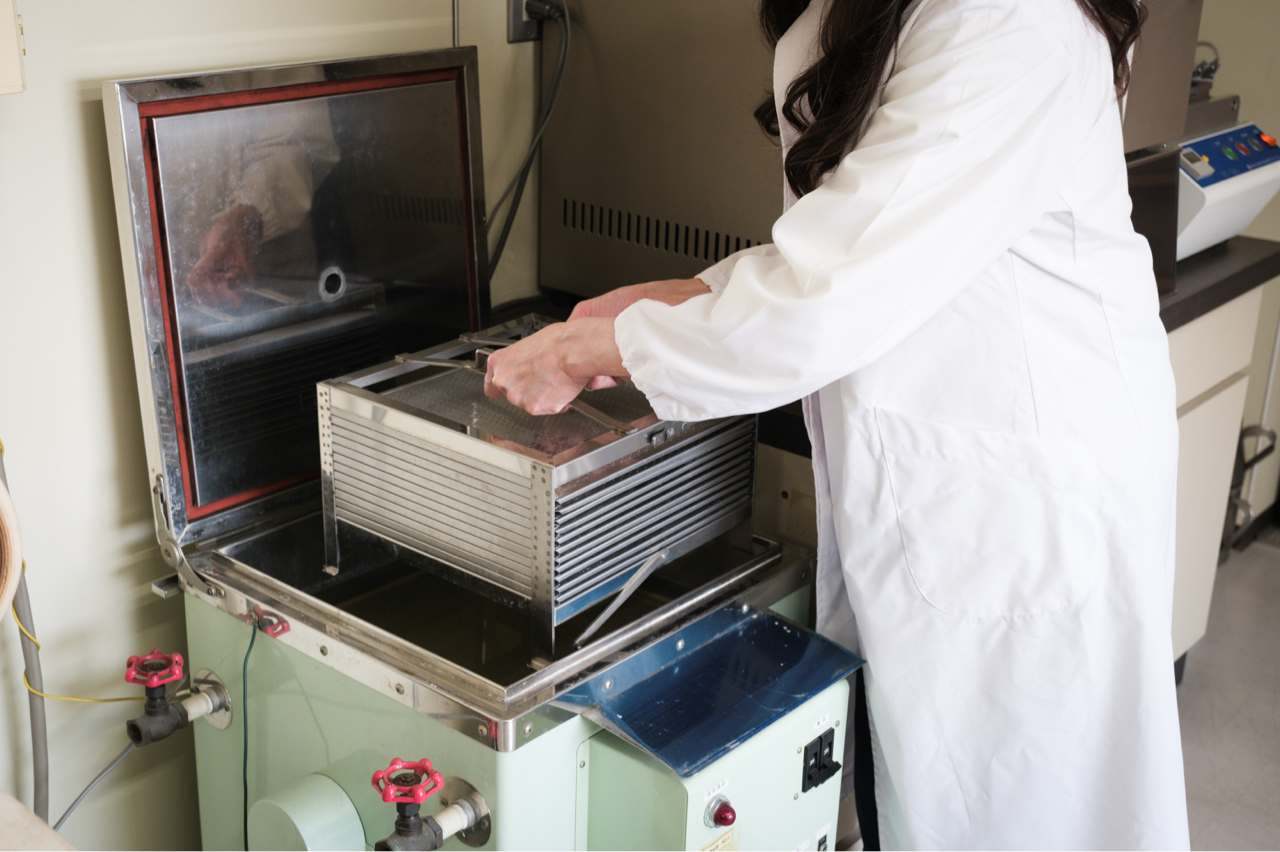

Washing test: - JJIS L 0844 No. A-2

This test ascertains the extent to which dyed products fade or color is transferred to grey, white, or other light-colored products due to washing in a washing machine.

Light resistance test: - JIS L 0842 No. 3 Exposure Method

"There are no dyed products that are completely resistant to fading or discoloration due to light or sunlight. The purpose of this test is to ascertain the extent to which this fading/discoloration is unlikely to cause problems in practical terms.

*Because it takes a long time to actually measure the degree of fading/discoloration under fluorescent lamps/direct sunlight, the dyed fabric is irradiated with light from a carbon arc lamp inside the testing machine to determine whether the degree of fading/discoloration is within the standard range. In the Level 4 test, the irradiation is equivalent to exposure to actual sunlight for seven to eight days in summer."

Dimensional change test: - JIS L 1096 D Method

This test measures dimensional changes to the cloth caused by washing.

Water repellency test: - JIS L 1092 Spray Test

This test ascertains how well the fabric repels water and also determines whether the product can be labeled water repellant.

SDGs

Aiming for world-class product quality

Through thorough quality control we aim to manufacture Japanese products at a world standard level and deliver these products from Kyoto to the world.

Main initiatives

- Maintenance of ISO 9001 accreditation

- Strengthening of our quality assurance management system through JIS-based product testing

- Traceability aimed at improving product quality

Environmentally friendly management

We endeavor to preserve the rich natural environment by achieving harmony between the natural environment and our business activities.

Main initiatives

- Maintenance of ISO 14001 accreditation

- Installation of equipment that will lead to a reduction in CO2 through participation in the Kyo-VER Soshutsu Sokushin Jigyo program

- Thorough implementation of measures to reduce waste, such as reusing leftover fabric and not using wrapping paper

Serving the people of the world

We endeavor to contribute to children’s healthy growth through various activities aimed at passing down traditional Japanese techniques over generations.

Main initiatives

- Conducting cloth dyeing experiential classes at local elementary schools

- Reviving the use of throstle yarn and generating local employment through the establishment of our Laos factory

- Donating stationary supplies to elementary schools in Laos

WORKSHOP

We conduct workshops providing insight into traditional techniques embodying the Japanese sense of beauty that has been passed down to the present day, creating an even greater sense of familiarity. From items that can be easily made to authentic products, we plan classes that anyone can enjoy.